It should be aligned with the strategic goals and vision of the organization. The cost of conversion analysis should not be done in isolation, but rather in conjunction with the overall strategy and vision of the organization. It should support and contribute to conversion cost formula the mission, values, and objectives of the organization, such as growth, innovation, sustainability, and social responsibility.

Grow Your Business With TranZact.

The cost of conversion is an important component of the cost of goods manufactured, which is the total cost of producing the goods that were sold during the period. However, the cost of conversion is https://www.bookstime.com/ not the same as the cost of goods manufactured, as there are some differences and similarities between them. In this section, we will explore these differences and similarities in more detail and provide some examples to illustrate them.

- A lower Cost Per Conversion often means a marketing campaign successfully transforms clicks into leads or customers without breaking the bank.

- Direct labor costs include the salaries, wages, and benefits paid to employees who work on the finished products.

- By understanding the nuances of conversion costs, businesses can enhance their financial performance and achieve sustainable growth.

- Understanding conversion costs is vital for businesses to maintain competitiveness and profitability in the manufacturing industry.

- It covers rent, utilities, depreciation on equipment, and any indirect labor costs (like maintenance staff).

- Evaluate Cost Per Conversion across online advertising channels like social, search, video, and display.

Example 1: Manufacturing Industry

However, they are not the same, and they have some important differences and similarities that need to be considered. By knowing how to calculate and compare these two concepts, you can improve your knowledge and skills in managing a manufacturing business. Prime costs and conversion costs are also different due to their presentations. The cost sheet is a document that is used to calculate the cost of a product. Conversion costs, however, are not presented on the cost sheet of a product.

Conversion Cost Formula

In a business that uses a high degree of automation, it is likely that manufacturing overhead costs will comprise the bulk of all conversion costs. In the case of high conversion costs, there is always room for improvement. We had to “top off” the beginning WIP units this period to complete them. So the cost of beginning WIP, the first-in and first-out portion of the units completed and transferred out is reflected below. Notably, “equivalent units completed with this period’s work” is calculated the same as in the first set of brackets below. If the process is constantly being repeated across homogeneous units, then we can consider a unit’s percent completion as an indicator of how much of the process’s overhead costs that unit has incurred.

Managing and Reducing Conversion Costs

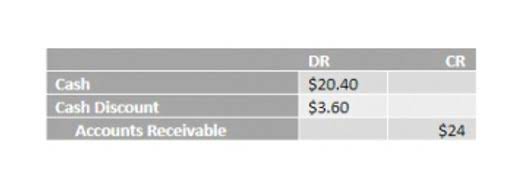

Conversion Cost Variance is a metric used to assess the variance between the actual conversion costs incurred and the budgeted conversion costs. It provides insights into the efficiency and effectiveness of the production process. By analyzing this variance, companies can identify areas of improvement and take corrective actions. The cost of a product is determined by the amount of labor and overhead needed to convert raw materials into finished goods. To calculate a conversion cost, add together the direct labor cost and the manufacturing overhead.

Suppliers may want to increase the cost of conversion to sell more raw materials, while competitors may want to decrease the cost of conversion to gain a competitive edge. Therefore, the cost of conversion analysis needs to balance and align the interests and objectives of different stakeholders. They impact profitability, competitiveness, and strategic decision-making. By understanding and managing these costs effectively, businesses can thrive in a dynamic manufacturing environment. This includes rent, utilities, machine repairs, and any other expenses incurred within the factory.

These individuals operate machinery, assemble products, and perform other labor-intensive tasks. Calculating direct labor cost involves multiplying the total hours worked by the labor rate (hourly or per unit). Prime costs are calculated based on the direct labour costs and the total cost of the raw materials.

CPA is a broader metric than CPC because it includes the cost of all the stages involved in acquiring a customer, such as lead generation, lead nurturing, and closing the sale. This calculation can be done during any marketing campaign and helps gauge its effectiveness and determine how much your business has made or lost. Customer Acquisition Cost, commonly known as CAC, represents the total expenses a business incurs to acquire a new customer.

- The timing of advertisements has always been important, and it has been a concern for brands from the era of television commercials.

- In summary, reducing conversion costs requires a holistic approach that combines technical optimization, strategic marketing, and continuous monitoring.

- How do companies keep track of their expenses, production, sales, and efficiency?

- The cost of conversion reflects the cost of producing the goods, while the cost of goods sold reflects the cost of selling the goods.

- A good average Cost Per Conversion varies by industry but should be significantly lower than the customer’s lifetime value.

- Conversion cost per unit is the average cost of converting one unit of product from raw materials to finished goods.

The cost of conversion is used for product costing and pricing decisions, while the cost of goods manufactured is used for performance evaluation and budgeting purposes. From a financial perspective, Cost of Conversion plays a vital role in determining the overall production costs and, consequently, the pricing strategy of the manufactured goods. By accurately calculating and analyzing the Cost of conversion, manufacturers can make informed decisions regarding pricing, cost control, and resource allocation. The cost of conversion analysis is not a one-time activity, but rather an ongoing process that needs to be monitored and measured regularly and continuously. Direct cost is any cost that can Debt to Asset Ratio be directly traced to a specific product or cost object.

Suppose a manufacturing company budgeted $100,000 for conversion costs for a particular production run. How to use conversion cost for cost accounting purposes, such as assigning costs to products, inventory valuation, and variance analysis. Manufacturing cost is the cost that company spends to support the production process but they cannot allocate to each product. They are the indirect cost that incurs to support the manufacturing, but it is very challenging to apply the cost to each production unit.